The Book of Breath - work in progress

In 2014 I created a small piece, consisting of a simple strip of mirror, onto which I wrote the words- Next to Nothing- with Rain X. Rain X is used on windshields to make the rain run off easier.As an ink it is invisible on the glass, but will inhibit the glass to fog over when breathing onto it.

In the summer of 2016 I started the Specialty Glass Residency in upstate New York. The Specialty Glass Residency is a joint program of The Corning Museum of Glass and Corning Incorporated that supports artists in exploring the use of specialty glass materials to inform their body of work.

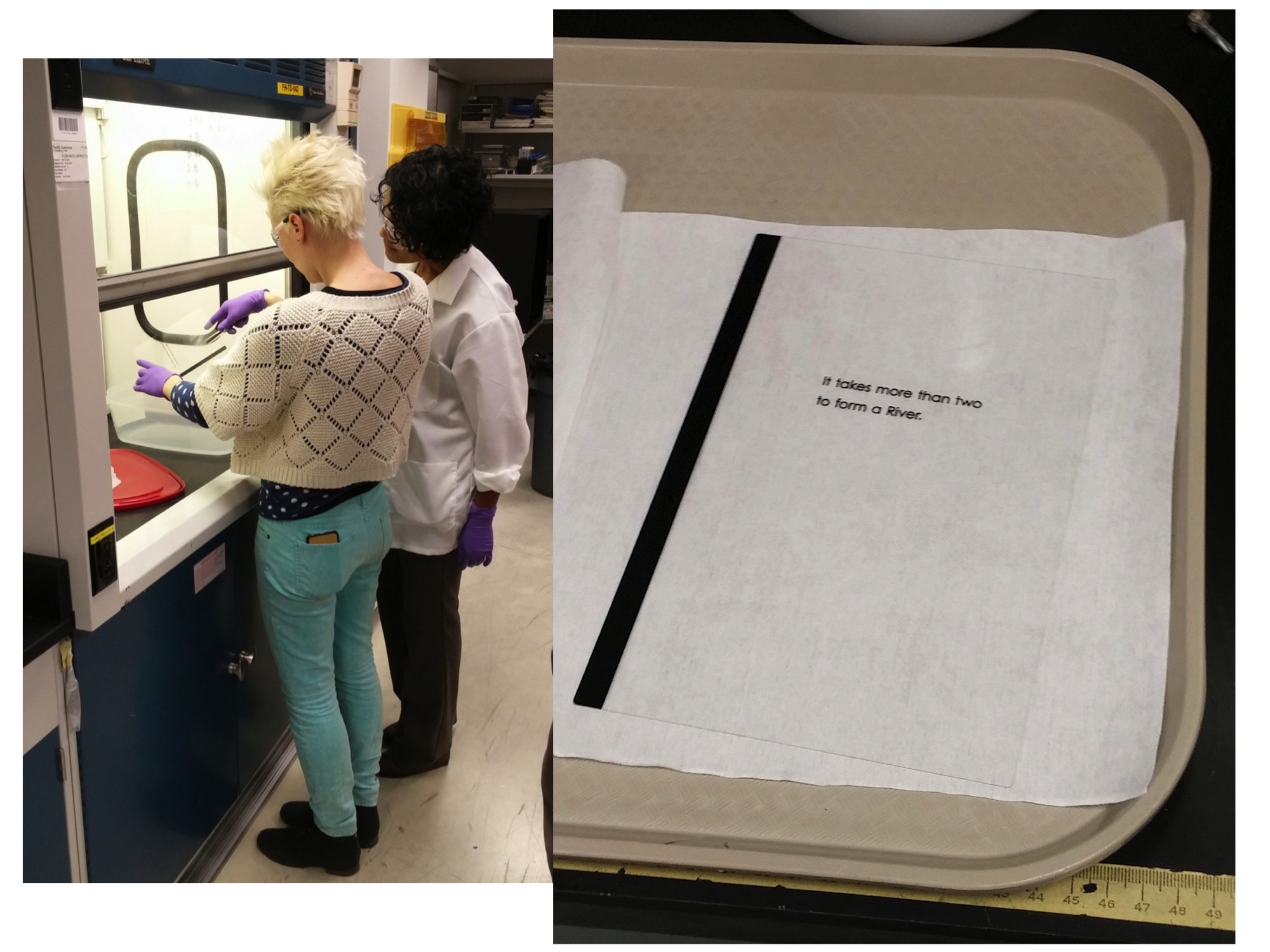

In connection with the Coatings Lab. at Corning Inc. I was able to expand the initial test into a book project. With the help of the incredible knowledgeable and talented Senior Research Scientist Wageesha Senaratne and Dr. Prantik Mazumder we figured out what coatings to use on the glass, how to avoid the coating processes to interfere with each other and how to use the thinnest glass possible for the pages of the book.

First piece from 2014, Next to Nothing.

Learning about the difference between hydrophillic and hydrophobic with Dr. Prantik Mazumder at Corning Inc.

The book making process at Corning was a multiple step process, after we had decided on layout, fond type, coating method and glass type.

We ended up using a 0.4mm thick Gorilla Glass. This is the type of glass we have in our mobile devices.

The glass had in the first step to be cut in the laser cutting lab. After cleaning we inkjet printed the text on the glass pages in Corning's printing lab. The black lettering was used as a resist stencil which we later removed after we had applied the first set of coatings.

In the laser cutting and printing lab with Matthew Fenton and Michael Gaj. Looking at the process of the book project.

After the printing was done, the pages were sent off to the coatings lab, where they received the first set of coatings. For this step the glass had to be ultra clean and the process is done in clean room environments to ensure that the coatings cover the glass without any faults.

After that we took over the last step of coatings and the removal of the inkjet print.

In the lab with Wageesha Senaratne coating pages. The solid black block at the edge of the page to the right is where the book binding will be. The printed ink resist ensures proper adherence for the binding, as the coatings we used are designs to prevent smudges. That would interfere with any glues used for the binding later on.

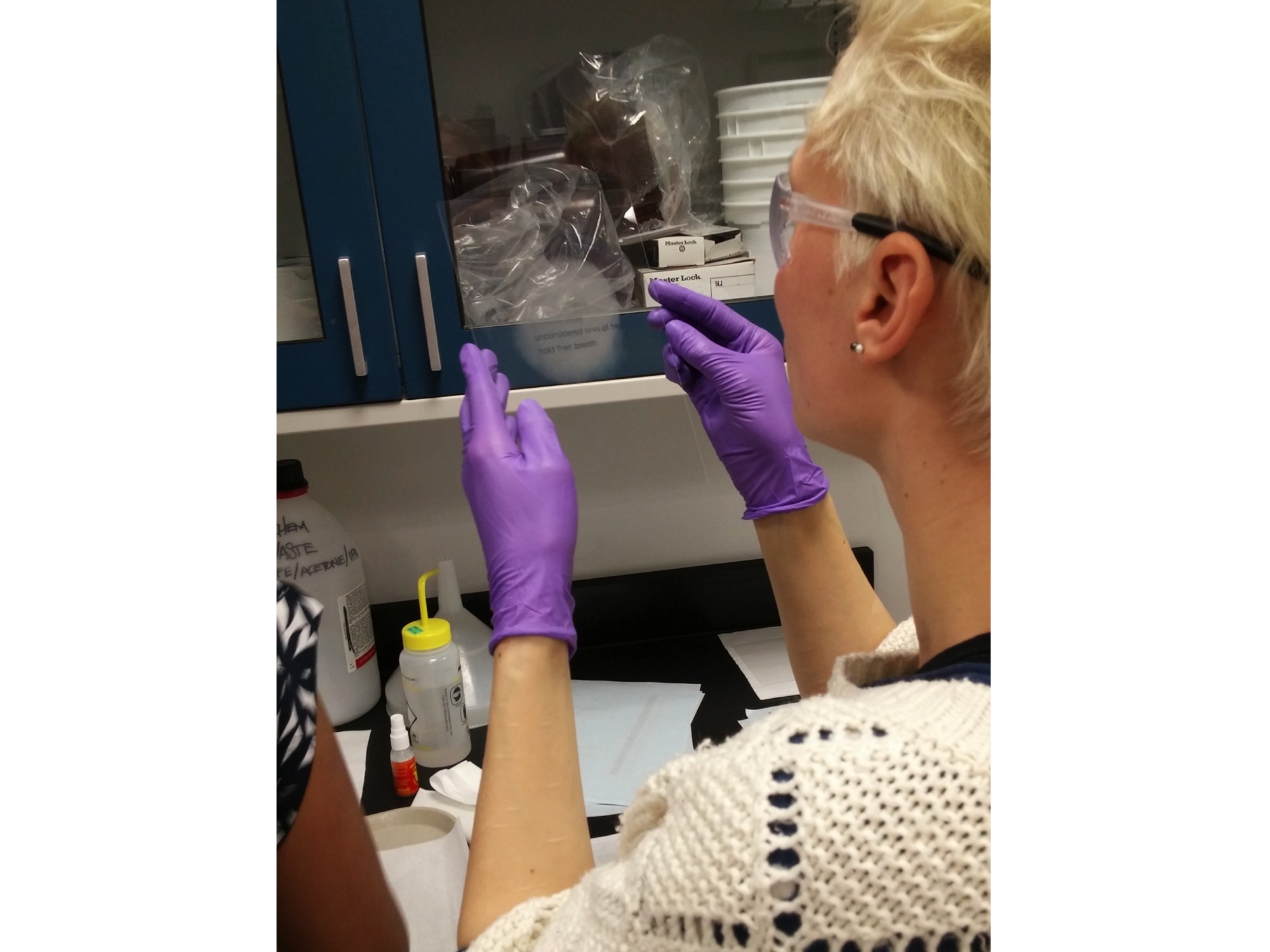

After the pages were coated we dipped them in a liquid that would lift off the ink from the page. A little help with a razor blade enabled us to remove it fully.

Scraping off the ink.

testing the coating quality in the finished pages.

Breath reveals the writing on the now completely clear page.

the text can also be filled with water and sits proud in the writing.

The next step now is to bind the book and make the case it will be in. Stay tuned.

This is the full book activated, page by page. I like particularly how the vanishing words transform the language and change the meaning of the sentences.

Here is each page of the book in print.